With ProSys megasonic systems and technology you can:

Increased PRE. No Adders. Easy implementation into batch and single-wafer equipment.

Typical applications

Substrate sizes

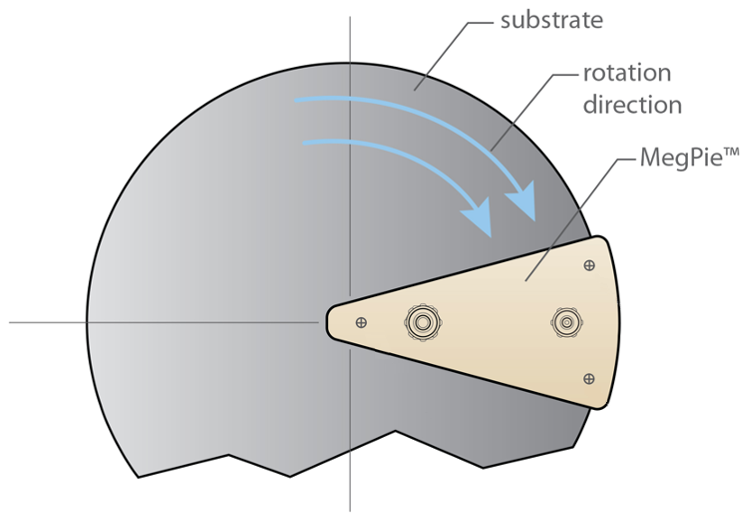

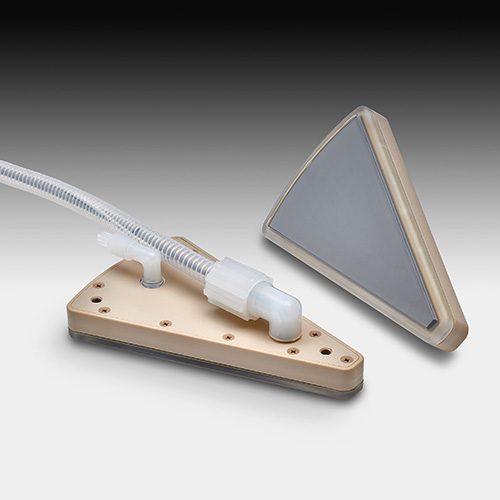

Due to the pie-shaped design of the MegPie™, each part of the wafer receives the same dosage of sonic energy. Leveraging our proprietary Direct Bonding Technology, all our transducer designs are enhanced with advanced RF electronics for optimal process control.

This leads to outstanding process uniformity, unmatched in the Semiconductor industry for more than 20 years.

Typical applications

Substrate sizes

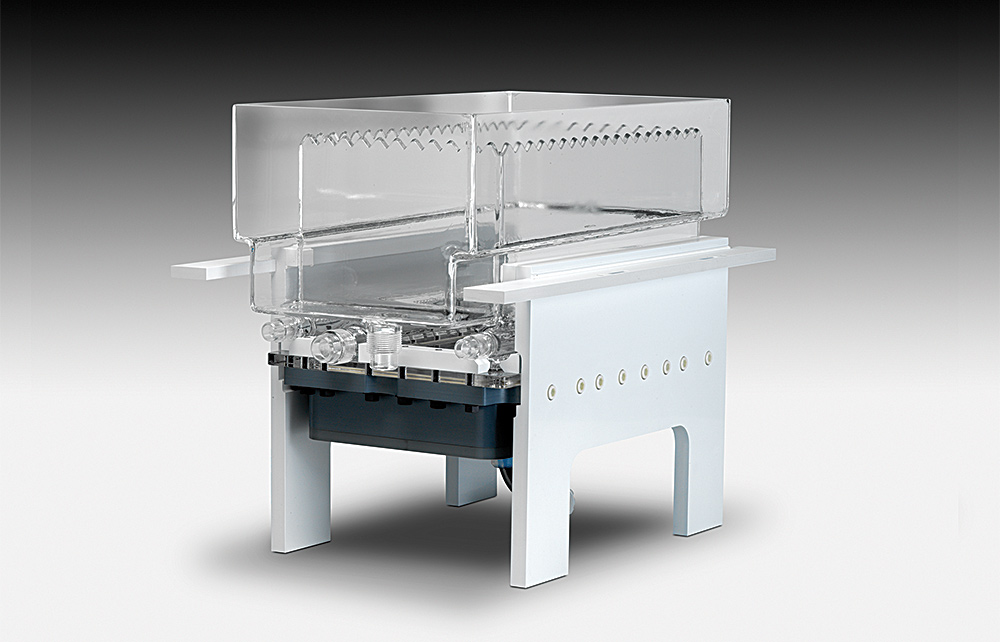

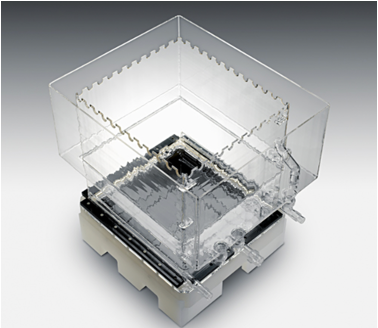

Complete Plug & Play solution for existing tank

with complete replacement of Brush Arm

easy-to-install upgrade for existing wet benches

At ProSys, we are confident in our advanced cleaning abilities. We understand the significance of cleanliness and efficiency, and that’s why our products consistently exhibit high PRE. The most effective method to truly appreciate the superiority of our megasonic system is by testing it within your facility, using your specific substrates, chemicals, and clean room conditions. Evaluating a ProSys system in your own setting offers not just crucial insights into process enhancements, but also firsthand experience of our unmatched preformance on your substrates.

Founded in 1996, Product Systems Inc. stands as a global leader in megasonic enhanced processing. With our headquarters in Campbell, California, and additional manufacturing in Germany, we specialize in creating state-of-the-art megasonic components for both batch and single wafer applications. Our commitment to quality is evident through our advanced RF electronics, ensuring precision in every process. Follow our journey on LinkedIn.

Advanced component design calls for finer structures, emphasizing nano-particle removal. Using ProSys Megasonic particles under 20 nm can be efficiently removed. Our goal? Supreme purity for optimal semiconductor performance.

ProSys elevates solar cell manufacturing with advanced cleaning technology, effectively stripping away impurities without compromising material integrity, even at elevated temperatures. Our robust, high-purity cleaning systems are the cornerstone of superior solar efficiency and longevity.

ProSys proudly partners with international research institutions , pooling collective expertise to advance megasonic enhanced process technology. Our collaborative efforts are shaping the future of enhanced wet process across multiple sectors, including enhancing semiconductor packaging processes.

ProSys also specializes in advanced megasonic cleaning for optics, ensuring uniform decontamination without damaging delicate components. Our technology excels in precision, removing particulates and residues, reaffirming our commitment to quality and flexibility in the optics industry.

Our megasonic cleaning solutions bring precision to the forefront of microelectromechanical systems (MEMS) fabrication. By focusing on removing residuals from TSV, developing high aspect ratio SU8 and cleaning the most sensitive diaphram structures and thereby preserving the integrity of fragile components.

In the critical field of medical device manufacturing, ensuring the sterility and cleanliness of each component is paramount. ProSys offers specialized megasonic process systems designed to meet the high-precision demands of the industry, providing thorough cleaning that underpins the reliability of medical diagnostics and treatments.

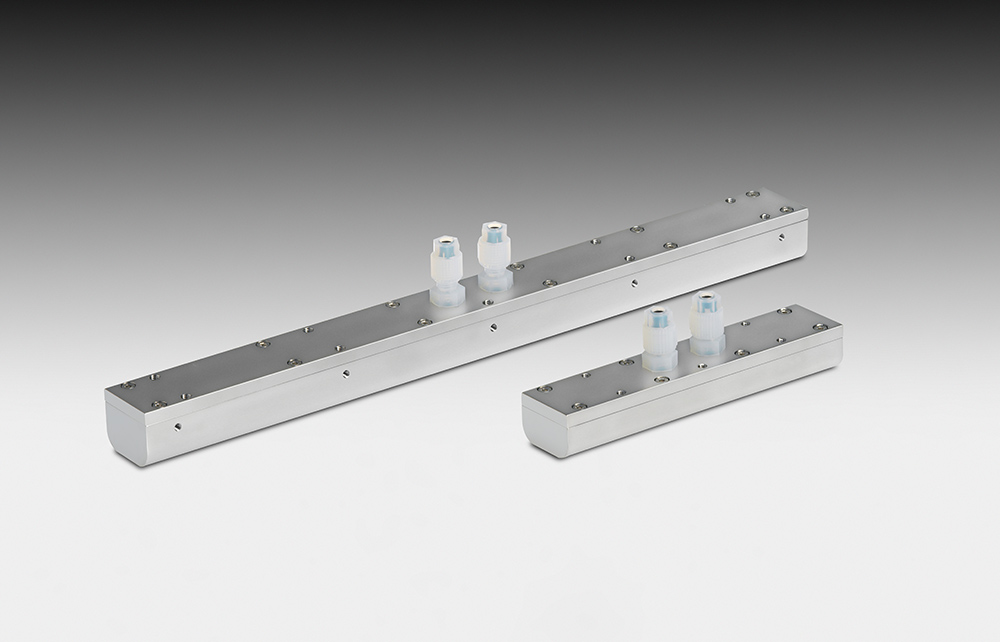

Patented devices quickly and safely remove contaminants from sensitive products, enhancing PRE.

Unlock superior semiconductor cleaning with ProSys Megasonic’s advanced systems. Achieve exceptional results and efficiency with our MegPie™ V3 and Quartz Tank System, engineered for precision and cost-effectiveness

Megasonic cleaning is a sophisticated process that employs high-frequency sound waves, typically above 800 kHz, to agitate a liquid medium. This agitation creates microscopic cavitation bubbles that implode with considerable energy, which in turn dislodges and removes contaminants from surfaces in a non-contact manner. This method is highly effective for precision cleaning and processing in various high-tech industries, including semiconductor manufacturing, where the utmost surface cleanliness is required.

ProSys megasonic technology operates at a much higher frequency compared to traditional ultrasonic cleaning systems. The higher frequency generates smaller cavitation bubbles, providing a gentler cleaning action suitable for delicate and micro-scale structures found in semiconductor wafers and other sensitive components. This results in effective and uniform cleaning with minimal to no damage to the substrate, a critical factor in many advanced manufacturing processes.

Megasonic cleaning is extremely versatile and is capable of removing an array of contaminants, including sub-micron particles, organic residues, photoresist, and various thin films that are commonly found on semiconductor wafers, photomasks, and other critical components. Its effectiveness makes it an essential process in the production of electronics where any residue can affect the performance of the final product.

ProSys megasonic systems are meticulously designed to ensure the uniform cleaning of delicate parts. By utilizing non-contact cleaning methods and regulating the acoustic energy precisely, our systems minimize mechanical and thermal stress on components, thereby maintaining the integrity of the most fragile substrates throughout the cleaning process.

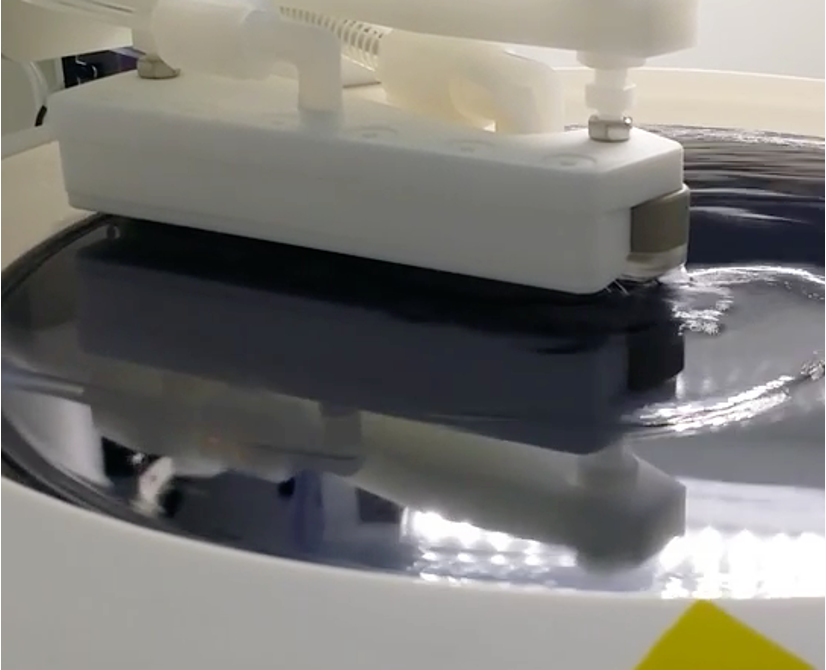

The MegPie™ V3 is ProSys’s proprietary megasonic transducer, engineered for the non-contact cleaning or sonochemical processing of a single rotating substrate. It emits a radially uniform dose of acoustic energy that translates into a consistent cleaning action across the entire substrate surface. This technology is particularly effective in reducing the potential for cross-contamination and ensuring high-yield outputs in sensitive manufacturing environments.

ProSys megasonic systems offer several operational cost benefits. They enhance the efficiency of the cleaning process, leading to reduced cycle times and lower consumption of chemicals and water. Additionally, the systems are designed to require less energy, which not only cuts down operating costs but also supports sustainability objectives. The durability and low maintenance requirements of our systems further contribute to a lower total cost of ownership.

The Quartz Megasonic Tank System embodies the forefront of cleaning technology. It distributes cleaning energy uniformly throughout the tank, mitigating the formation of ‘hot spots’ or areas of excessive energy that could damage sensitive parts. Moreover, the system integrates seamlessly with existing processes, enhancing throughput and improving the consistency and reliability of the cleaning outcomes.

To ensure reliability, ProSys megasonic systems incorporate advanced monitoring capabilities that provide real-time feedback on the cleaning process. This enables precise control over the acoustic energy, allowing for immediate adjustments to maintain optimal cleaning conditions. Our systems’ design also includes fail-safes and diagnostics that help predict maintenance needs, ensuring minimal downtime and consistent performance.

The ProSys megasonic systems are optimized for high Particle Removal Efficiency (PRE), capable of removing particles down to 19 nm at a rate of 98% or higher while adding ZERO particles. This is particularly crucial in industries where even the smallest particle contamination can lead to product failure. Our systems are tested and proven to meet stringent cleanliness specifications, ensuring your products are free from defects.

ProSys provides comprehensive support to determine the suitability of megasonic cleaning for various applications. Our team of experts can conduct detailed analysis and trials to identify the most effective cleaning frequencies, power settings, and process parameters tailored to your specific needs. We offer Demo testing and process development services to ensure that our megasonic cleaning solutions meet and exceed your expectations for cleanliness and efficiency.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

With a storied career that has significantly shaped the field of materials science, Dr. Srini Raghavan stands as a pillar of innovation and expertise at ProSys.